Elevate your Business

with Newcomb Spring's Design Assistance

- Originally published by Abbi Gillette

Are you feeling overwhelmed by Google’s complex explanations of spring design? Feeling lost in an ocean of technical terms that don’t make sense? Let Newcomb Spring simplify the process and be your trusted spring design guide. We’ll save you from the headache and potential disaster of attempting a DIY approach for your product.

Kevin’s Story: Muddy Bottom Mini Trucks

Cricket Rumsey, General Manager at Newcomb Spring of Texas, recalls the day Kevin Seymour reached out to him.

“Kevin bought some aftermarket [springs] that didn’t work, and he needed something different, but he wasn’t sure exactly what he needed. He brought in the stock spring and the underperforming aftermarket spring and began discussing his vision for the design.”

Kevin’s vision extended beyond the functionality of the spring; he wanted a stronger spring that performed exceptionally well but also stood out visually among other suspension springs on the market. Cricket and the team got to work designing a working prototype that achieves the balance of visual progressiveness desired while adhering to specific dimensions needed functionally for the PowerFlex design.

The prototyping phase continued to be a collaborative effort. The Texas team meticulously crafted samples, ensuring the physical appearance of the suspension spring didn’t compromise its functionality. Kevin actively participated and spent an entire day on the production floor fine-tuning the design with the team. The efforts of both Newcomb and Kevin paid off when they achieved a sample that closely matched Kevin’s desired product.

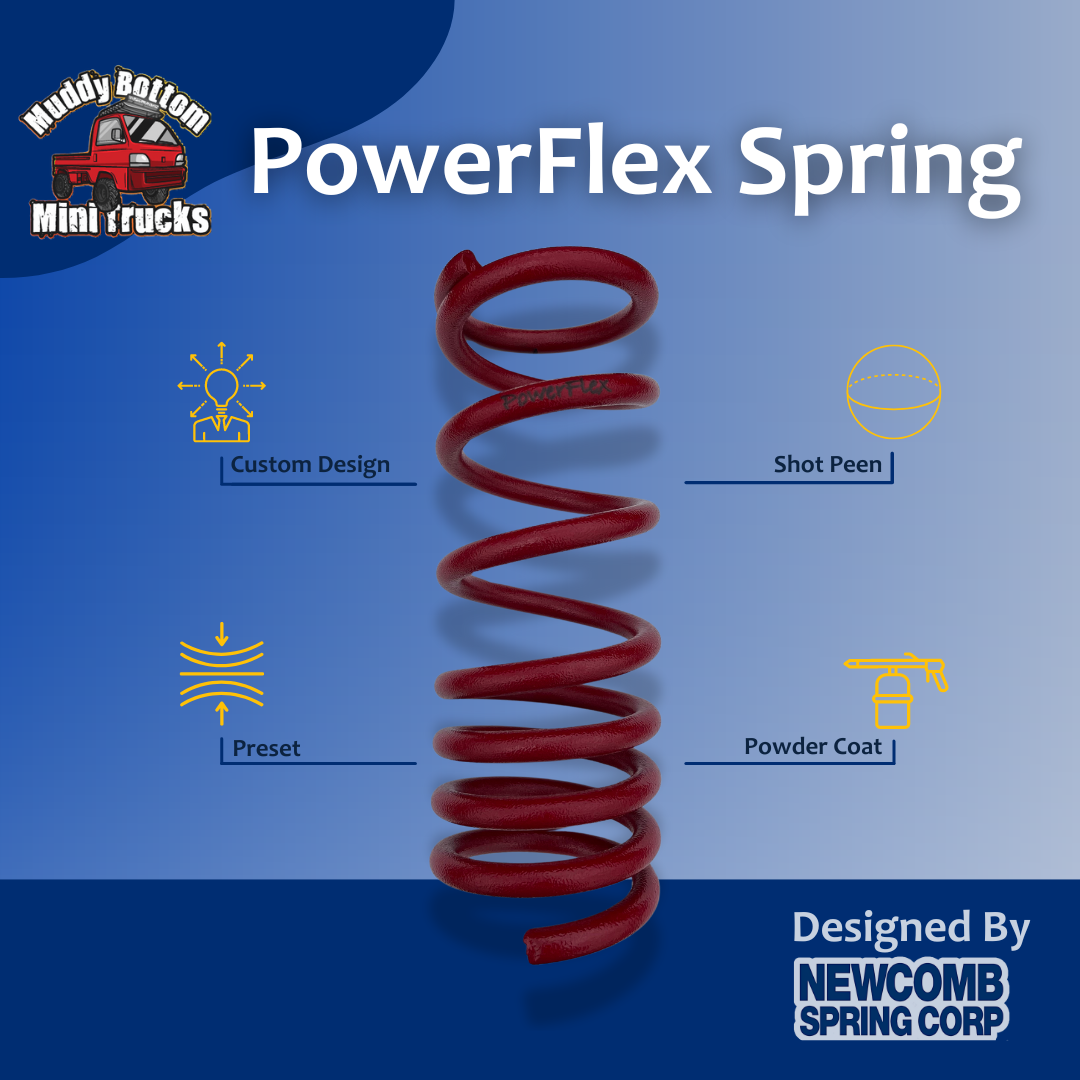

The Product: PowerFlex Suspension Spring

Designed for durability and aesthetic appeal, the PowerFlex suspension spring undergoes several specialized processes to enhance its functionality, such as shot peening, presetting, and powder coating.

The spring is expertly engineered with a progressive design that significantly boosts its performance. It features variable pitch with certain coils absorbing minor bumps while others activate only to absorb larger forces such as potholes and off-road terrain. This design progressively increases the spring rate as it compresses, allowing the spring to handle transitions in terrain smoothly. This innovative design makes for a smoother ride and reinforces its durability.

When asked why he chose Newcomb Spring over the other spring companies he contacted, Kevin explained how the team at our Texas facility was more than willing to work with him when other spring makers were not.

“They had to do a lot of educating me so that I knew what I was asking for. The end product is so much better because of that. There’s a lot more to making springs than I had any clue of.” Kevin remarks.

How has collaborating with Newcomb Spring benefited Muddy Bottom Mini Trucks?

“It’s my design! No other springs out there perform as well as these now. It is a unique spring only for my business and nobody can replicate that. Our customers love them!” exclaims Kevin. He sells the PowerFlex suspension springs at his company, Muddy Bottom Mini Trucks. View his inventory and learn more about his business at their website and see the PowerFlex spring in action in the gallery and on social media!

Don't wait until it's too late!

“Many engineers don’t contact us until it’s too late and they’ve backed themselves into a corner. We want to be at the forefront of the design, so we can work together to create a spring that will function best for your unique design.” Cricket states. When it comes to spring design, timing matters, waiting until the end of a project to address spring specifications can lead to costly setbacks. At Newcomb, we encourage proactive collaboration from the start.

Here are a few reasons why you should include our expertise early on in your project:

- Precise Specifications: Many designs require strict physical specifications. Our spring experts will work with you so that the design meets both physical and functional requirements ahead of time.

- Unique Solutions: Newcomb stands out among other spring companies because we work closely with you. Whether you have a product idea or need guidance, we will develop a custom solution with you. Our dedicated Kando Tech Centers provide modern technology and collaborative expertise to deliver a custom product you’re proud of.

- Cost-Effective Design: We offer more than just design assistance; our engineers and sales experts can suggest ways to lower costs without compromising quality when possible. We want to give you the best bang for your buck while upholding high-quality standards.

- First in Forming: Newcomb Spring’s ongoing commitment to excellence shines through our additional services. From custom components to innovative precision designs, we are proud to be First in Forming.

“If you have a product or an idea, and you don’t know exactly what you need, Newcomb is the company that will work with you, and develop this with you. That’s what sets us apart from other spring companies.” - Cricket Rumsey

Ready to kickstart your design or improve your existing product? Request a Quote today or reach out to sales@newcombspring.com!