Custom Wire Forms

As a custom wire form manufacturer with over a century of design and manufacturing experience, Newcomb Spring produces wire forms in a large range of shapes, sizes, and designs to meet your unique specifications. Our precision CNC machines provide fast, accurate, and efficient wire forming services.

Newcomb Spring also offers design assistance of your wire form manufacturing order, working with you to lower production costs and review your part's fit and function.

Get a Wire Form QuoteWire Form Capabilities

Material Shapes & Sizes

- .004 to .625 Inches (.100 to 15.875mm) in wire diameter

- Up to 2 inches (50mm) in bar stock

- Round wire

- Square wire

- Rectangular wire

- Special section wire

Wire Form Value Added Services

The following are only a portion of popular value added services we offer; this is not a comprehensive list. Please contact your local Newcomb Spring and discover what we can offer on your unique design.

Wire Form Design Information

What are Wire Forms?

Wire forms are versatile and custom-shaped wires designed to perform specific mechanical functions. They are created using various types of wire in a multitude of shapes and sizes, tailored to meet specific application needs. Wire forms are integral in industries such as electronics, automotive, and appliances where precise metal components are crucial for operational success. The design process for wire forms is complex, requiring careful consideration of the wire's shape, strength, and flexibility to ensure optimal performance in its final application.

Design Assistance

Designing effective wire forms requires attention to detail regarding material selection, bend radius, and load requirements. Factors such as the type of wire, its diameter, and the angles at which it is bent play a critical role in the performance and durability of the wire form. Our engineering team is equipped to assist in optimizing your wire form designs, ensuring that they meet both functional and aesthetic requirements. We provide tailored solutions that enhance the effectiveness of your wire forms, ensuring they integrate seamlessly into your products.

Wire Form Applications

- Aerospace

- Appliances

- Automotive

- Electronics

- Farm Machinery

- Furniture

- Medical Devices

- Sporting Goods

- Tools

- Toys

- Levers & Switches

- Fitness Equipment

- Industrial Machinery

- and more!

Wire Forms Prototyping

Recent advances in CNC manufacturing technology have significantly lowered the cost of creating prototypes of complex wire form parts. The Newcomb engineering staff gladly assists customers with part design, and we often produce wire form prototypes to help make sure components will fit spatial requirements. Modern prototypes often can be changed and reproduced in minutes, saving time, lowering costs and avoiding design errors.

Design Considerations

Maintaining quality, controlling production costs, and being sure the parts we manufacture are optimally suited to your application is what drives us. Our engineering and production teams are ready to assist in the manufacturing of prototypes to produce parts that best fit the form and function of your application. Let Newcomb Spring enhance your product with our design assistance and prototyping capabilities.

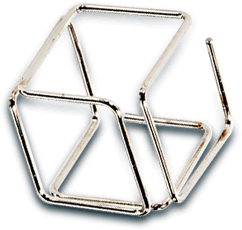

Product Gallery

Below are just a small selection of the wire form shapes we have produced, including:

- Clamps

- Cotter Pins

- D Rings

- Eyelets

- Guide Wire

- Handles

- Hanger Forms

- Hinged Clamps

- Latch Forms

- Trip Wire

- Wire Brackets

- Wire Supports