Custom Metal Stampings and Flat Springs

Newcomb Spring specializes in delivering high-quality, precision metal stampings and custom flat springs tailored to your strict design requirements. Our metal forming department uses four-slide technology for high precision stamping manufacturing.

With more than a century of experience in spring design and manufacturing, our team is ready to assist with your order. We collaborate closely with you to enhance your design, helping to reduce production costs and ensure optimal fit and functionality for your parts. This is crucial with sheet metal forming, as tooling and material can be costly to replace due to design errors.

Get a Metal Stamping Quote Try our Spring CalculatorMetal Stamping and Flat Spring Capabilities

Material Shapes & Sizes

- .006 to .625 inches (.152 to 15.875mm) in wire diameter

- Up to 5 inches (127mm) in bar stock

- #3 slit edge

- #5 deburred edge

- #1 round edge

- and more

Metal Stamping and Flat Spring Value Added Services

The following are only a portion of popular value added services we offer; this is not a comprehensive list. Please contact your local Newcomb Spring and discover what we can offer on your unique design.

Metal Stamping and Flat Spring Information

Metal Stampings vs Flat Springs

Although sometimes used interchangeably, there is indeed a difference between metal stampings and flat springs. Metal stampings are components that have been cut, shaped, or pressed into a specific design. They are not usually designed to move flexibly or bend repeatedly, but rather are sturdy.

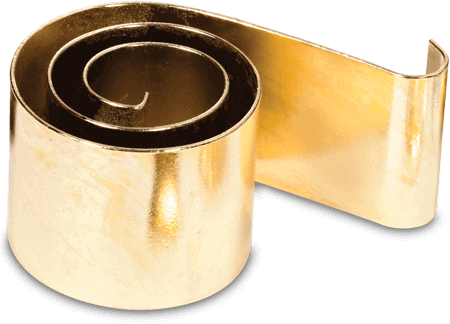

Flat springs on the other hand, are typically made to be flexible with the intent of returning to their original shape after being bent. They are usually thin, flat pieces of metal that bends when force is applied and releases back to their original shape once the force is removed.

Metal Stampings & Flat Springs Design

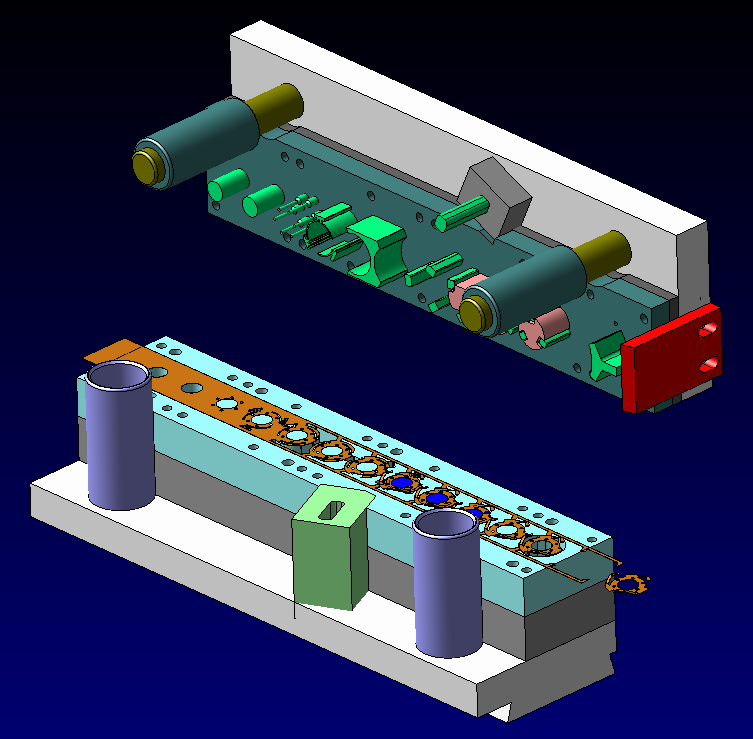

Newcomb Spring is equipped to produce precision metal stamping and flat spring components from sheet material or etched blanks. For high-volume manufacturing runs, we typically utilize hard tooling that can withstand long or repeated production runs. Due to the costly nature of producing these parts, it is often recommended to order a short run of parts to verify the component’s functionality in its application to avoid expensive design errors. Working with Newcomb Spring’s design assistance department can assist in reviewing the part’s fit and assist in avoiding these errors; one important reason to make us your preferred stamping plant.

Metal Stampings & Flat Springs Production

The extensive variety of equipment we utilize to produce stampings, strip forms, and flat springs, combined with our use of form tools, allows Newcomb Spring to create complex shapes as well as produce die sets that can be used for cutting, etching, extruding, notching, swedging, stamping, and more. Our facilities also offer primary and secondary operation departments, which work to produce short-order flat form components.

Whenever possible, metal stampings and flat springs should be designed to bend against the grain of material (i.e. perpendicular to the grain) to improve the life expectancy and reduce the risk of fracturing. For more guidance on your design, contact us today!

Metal Stamping & Flat Spring Applications

- Aerospace

- Appliances

- Automotive

- Electronics

- Farm Machinery

- Furniture

- Medical Devices

- Sporting Goods

- Tools

- Toys

- Levers & Switches

- Fitness Equipment

- Industrial Machinery

- and more!

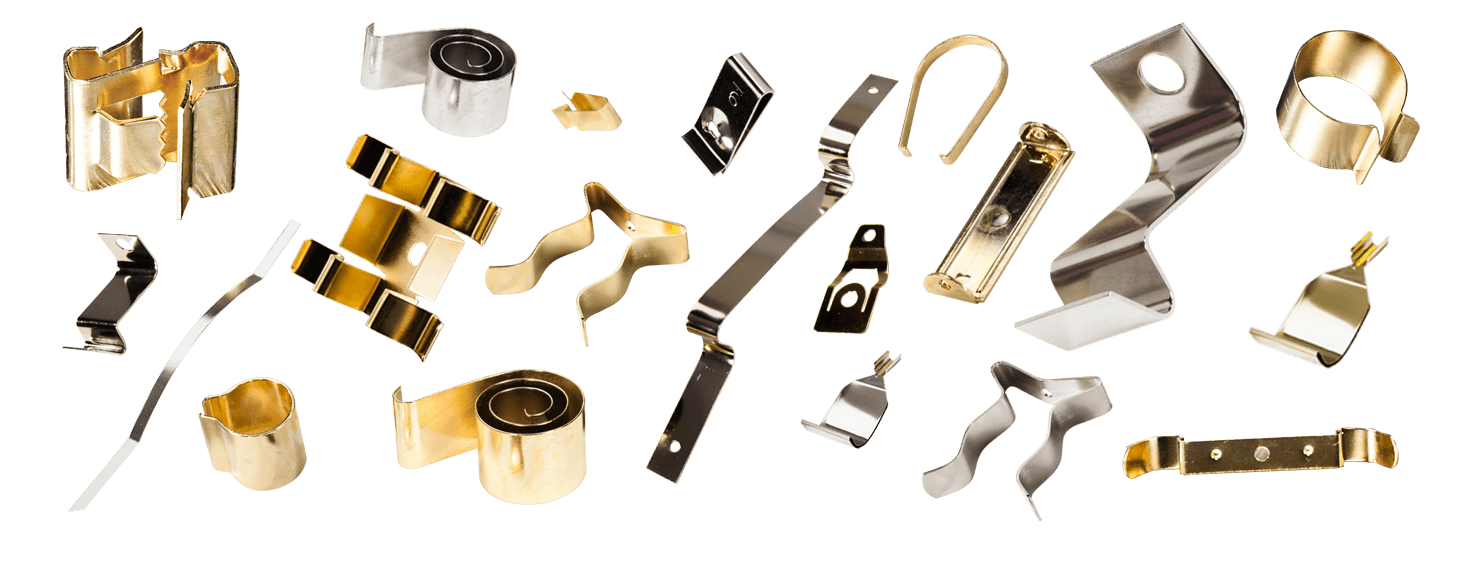

Product Gallery

Below are just a small selection of the metal stamping and flat spring types we have produced, including:

- Battery Contacts

- High Amp Clips

- Metal Tabs

- Quick Release Retainers

- Spring Loaded Links

- Sear Springs

- Trigger Connectors

- Trigger Ejectors

- Slide Lock Springs

- Receptable Retainers

- Handle Detents

- Spring Clips

- Heat Sink Weights

- Breaker Clips

- and more