Custom Torsion Springs

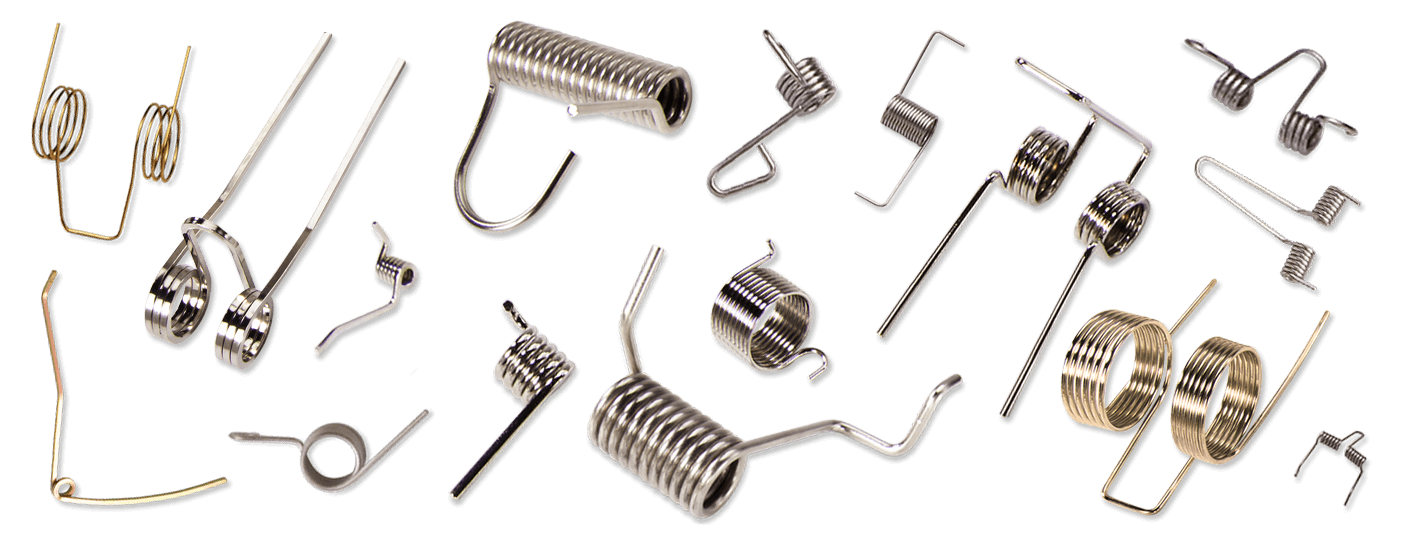

Newcomb Spring can produce a wide variety of custom torsion spring and double torsion spring shapes, sizes, and designs. All Newcomb parts are precision manufactured to meet even the strictest order requirements and quality expectations.

With over a century of spring design and manufacturing experience, we can provide design assistance on your custom torsion spring order. We work with you to lower production costs and review your part’s fit and function to optimize your part for your application.

Get a Torsion Spring Quote Try our Spring CalculatorTorsion Spring Capabilities

Material Shapes & Sizes

- .0015 to .625 inches (.038 to 15.875mm) in wire diameter

- Up to 2 inches (50mm) in bar stock

- Round wire

- Square wire

- Rectangular wire

- Special section wire

Torsion Spring Value Added Services

The following are only a portion of popular value added services we offer; this is not a comprehensive list. Please contact your local Newcomb Spring and discover what we can offer on your unique design.

Torsion Spring Design Information

What are Torsion Springs?

Torsion springs are used to store rotational energy and release that energy as torque to return to its natural position. This twists the object around the springs axis, allowing for a variety of applications. One common application is the opening and closing of objects; from doors to trash can lids and chip clips. Another use of its rotational forces are for clocks with a pendulum, allowing it to swing back and forth. Other applications can be seen in a vast array of automotive uses and medical equipment, among others.

Design Assistance

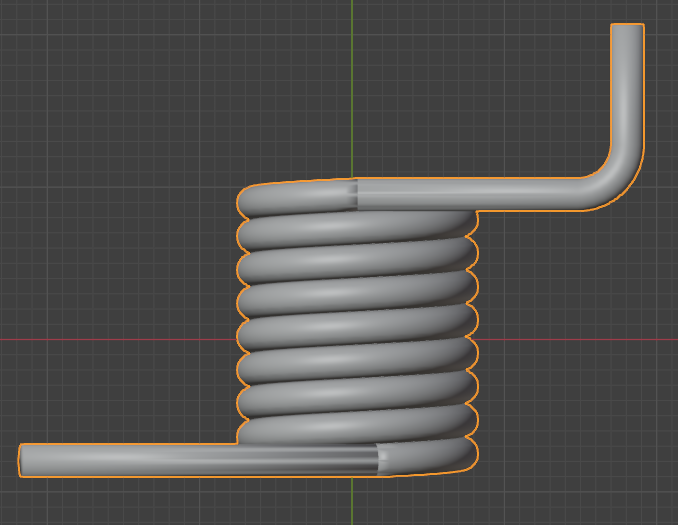

With new manufacturing techniques, torsion end positions can be held to surprisingly close tolerances. Newcomb is a custom torsion spring manufacturer with modern forming machinery and production techniques that allow for a variety of torsion spring end shapes. If you need help with designing your product’s torsion spring, our experienced sales engineers are just a call away. Let us help you optimize your next project for maximum efficiency and cost-effectiveness.

Torsion Spring Ends

Below are a few of the most common torsion spring end types. Consult a Newcomb Spring design expert on the end type that will optimize your spring's performance.

Bent Ends

Bent ends allow the spring to hook into or press against other components in the assembly, ensuring a secure fit and targeted torque delivery.

Get a quote

Double Torsion

Double torsion springs can carry twice the load that a single torsion spring can handle. Each half operates independently, providing balanced forces that enhance the spring's functionality and durability.

Get a quote

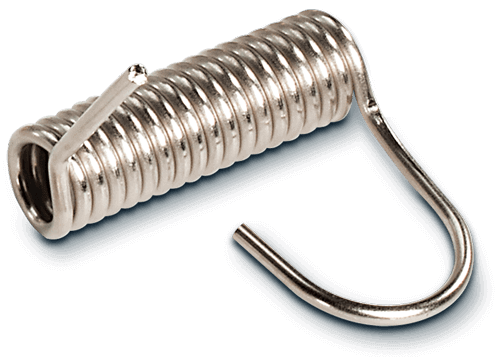

Hook Ends

Hook ends facilitate easy attachment for applications requiring a secure, yet detachable connection.

Get a quote

Cross Center

Cross center ends allow for balanced torque distribution and ensures that the spring can be securely anchored at multiple points.

Get a quote

Twisted Ends

Twisted ends allow for flexibility in mounting and helps distribute the torque more evenly. They can be adapted to engage with slots or other components in an assembly.

Get a quote

Axial

Axial ends are designed to align along the axis of the spring, enhancing the direct application of torque to the assembly.

Get a quote

Custom Ends

Custom ends are tailored specifically to meet unique application requirements. These ends can be designed in a variety of shapes, sizes, and orientations to perfectly align with the mounting and operational demands of the equipment.

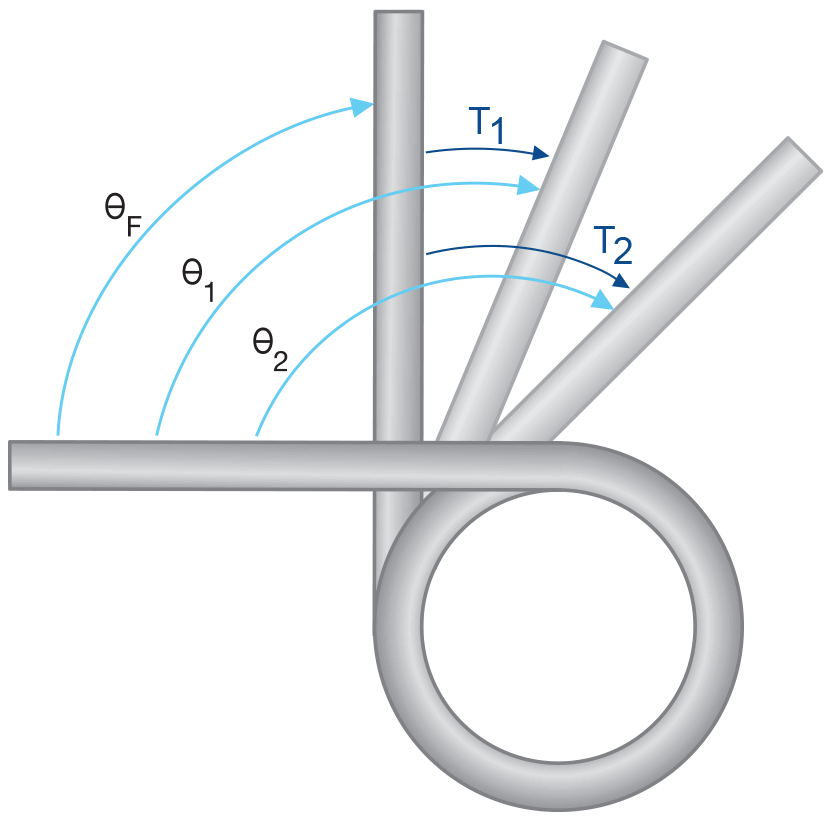

Get a quoteSpring Load

It is important to consider the direction of loading when designing bends or forms of a torsion spring's body or legs. Favorable residual stresses can be created when bends are loaded in a direction that reduces the radius or curvature.

Spring Load

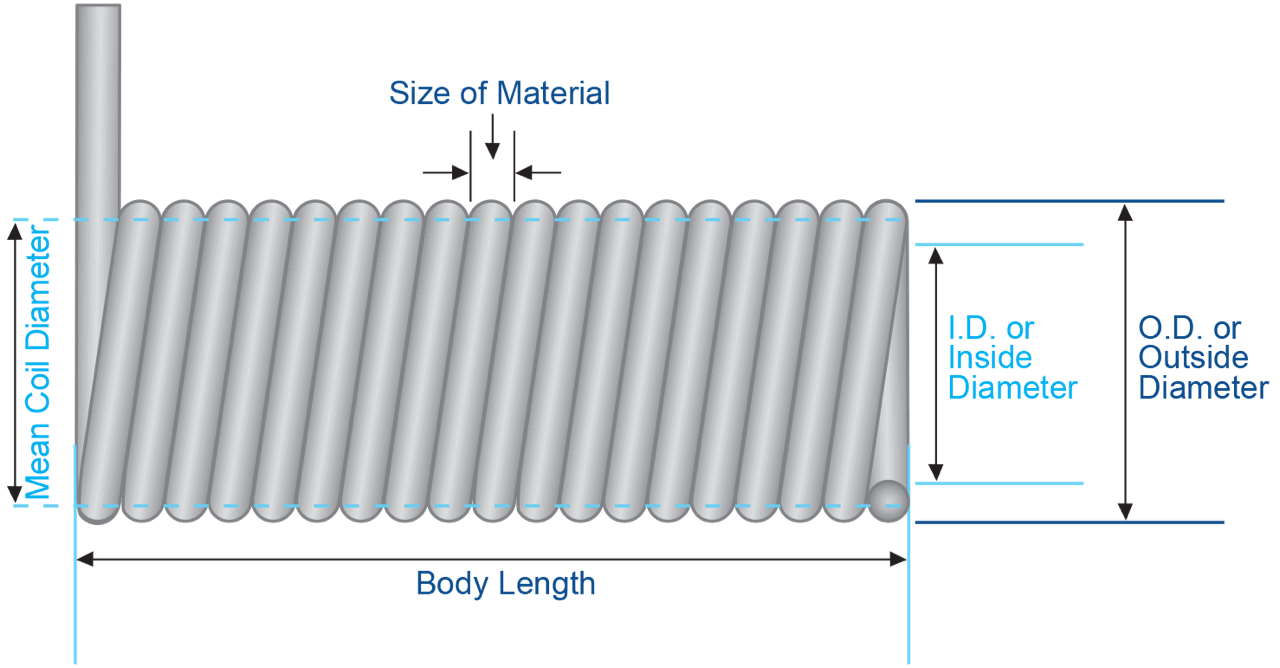

A torsion spring can be closed or open-wound and usually is designed to wind up. As a spring winds up, the coil diameter will decrease and the body length will increase. Read more on the direction of spring winding in our technical articles. It is always best to design torsion springs to wind up in use and to apply force in the direction of the wind – otherwise unfavorable bending stresses will occur. As a spring deflects in the direction of the wind, its diameter will decrease and its body length will increase. In these situations it is recommended that the torsion spring be supported on its inner diameter (I.D.) with a shaft or tube, sized so that there will be no binding due to deflection.

Torsion Spring Applications

- Aerospace

- Appliances

- Automotive

- Electronics

- Farm Machinery

- Furniture

- Medical Devices

- Sporting Goods

- Tools

- Toys

- Levers & Switches

- Fitness Equipment

- Industrial Machinery

- and more!

Product Gallery

Below are just a small selection of the torsion spring shapes we have produced, including:

- Brush Spring

- Clipboard Spring

- Closer Spring

- Double Torsion Spring

- Extended Leg Torsion Spring

- Hanger Spring

- Hinge End Torsion Spring

- Latch Spring

- Tine Spring

- Torsion Spring with Hook Ends

- Torsion Spring with Cross Body Bends