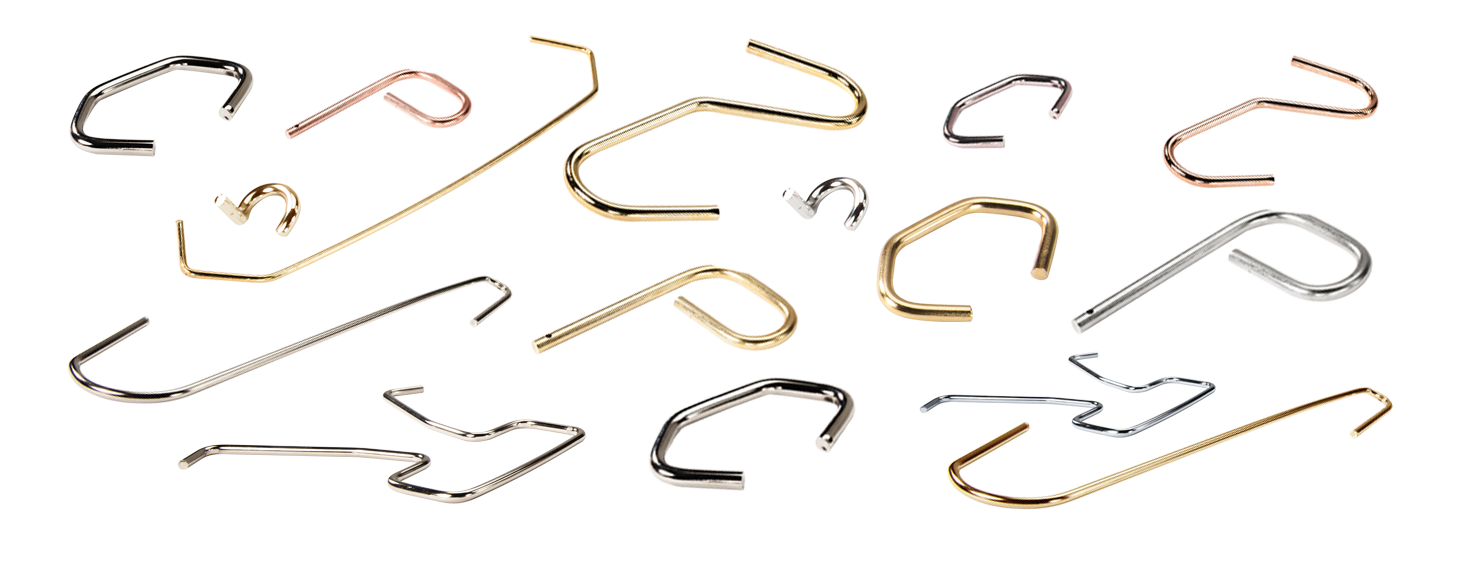

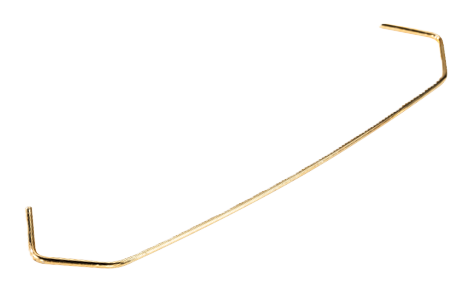

Custom Hooks

Newcomb Spring specializes in delivering high-quality precision engineered metal hooks tailored to your strict design requirements. We can produce a wide variety of shapes, configurations, and designs with an array of materials to choose from.

With more than a century of experience in metal forming and manufacturing, our team is ready to assist with your order. We collaborate closely with you to enhance your custom metal hook design, helping to reduce production costs and ensure optimal fit and functionality for your parts. Our custom metal hook manufacturing team will deliver top-of-the-line products for your end application.

Get a Hook QuoteHook Capabilities

Material Shapes & Sizes

- .0015 to .625 inches (.038 to 15.875mm) in wire diameter

- Up to 2 inches (50mm) in flattened wire

- Round wire

- 1/2 Round wire

- Square wire

- Flattened Wire

- Rectangular wire

- Special section wire

- and a large variety of materials available

Hook Value Added Services

The following are only a portion of popular value added services we offer; this is not a comprehensive list. Please contact your local Newcomb Spring and discover what we can offer on your unique design.

Battery Spring and Contact Design Information

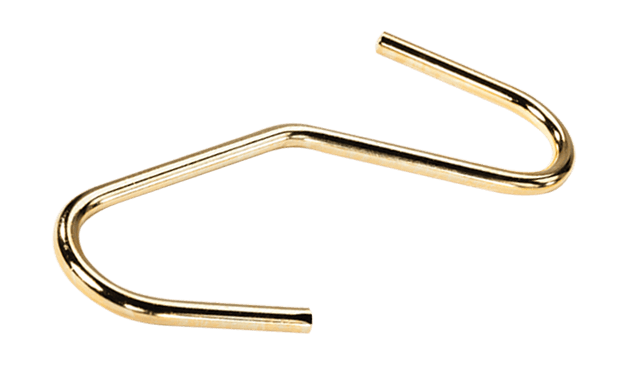

Metal hooks are designed to provide support by holding or hanging items. They’re created to withstand weight and pressure, maintaining their original shape with little give after the load is removed, making them suitable for a range of applications. These durable metal hooks are utilized in paint shops to powder coat products, in butcher shops to hang meat, and in so much more! There are many design considerations that must be taken into account during the design process to ensure optimal hook performance.

Newcomb Spring offers design assistance to optimize your product. Whether you’re looking to reduce production costs, enhance its functionality, ensure the fit of the product, or more, we’ve got you covered.

Design Considerations

When designing metal hooks, the choice of material is crucial, as it must endure the specific loads and environmental conditions expected. Steel is preferred for its strength, stainless steel for its corrosion resistance, and aluminum for its light weight. The design must also incorporate a suitable load capacity, ensuring the hook can handle stresses without failing.

The shape and size of the hook are critical for functionality, ensuring it fits the space and securely holds the intended items. Additionally, it’s essential to apply appropriate surface treatments, like powder coating, to enhance the hook’s durability and resistance to wear.

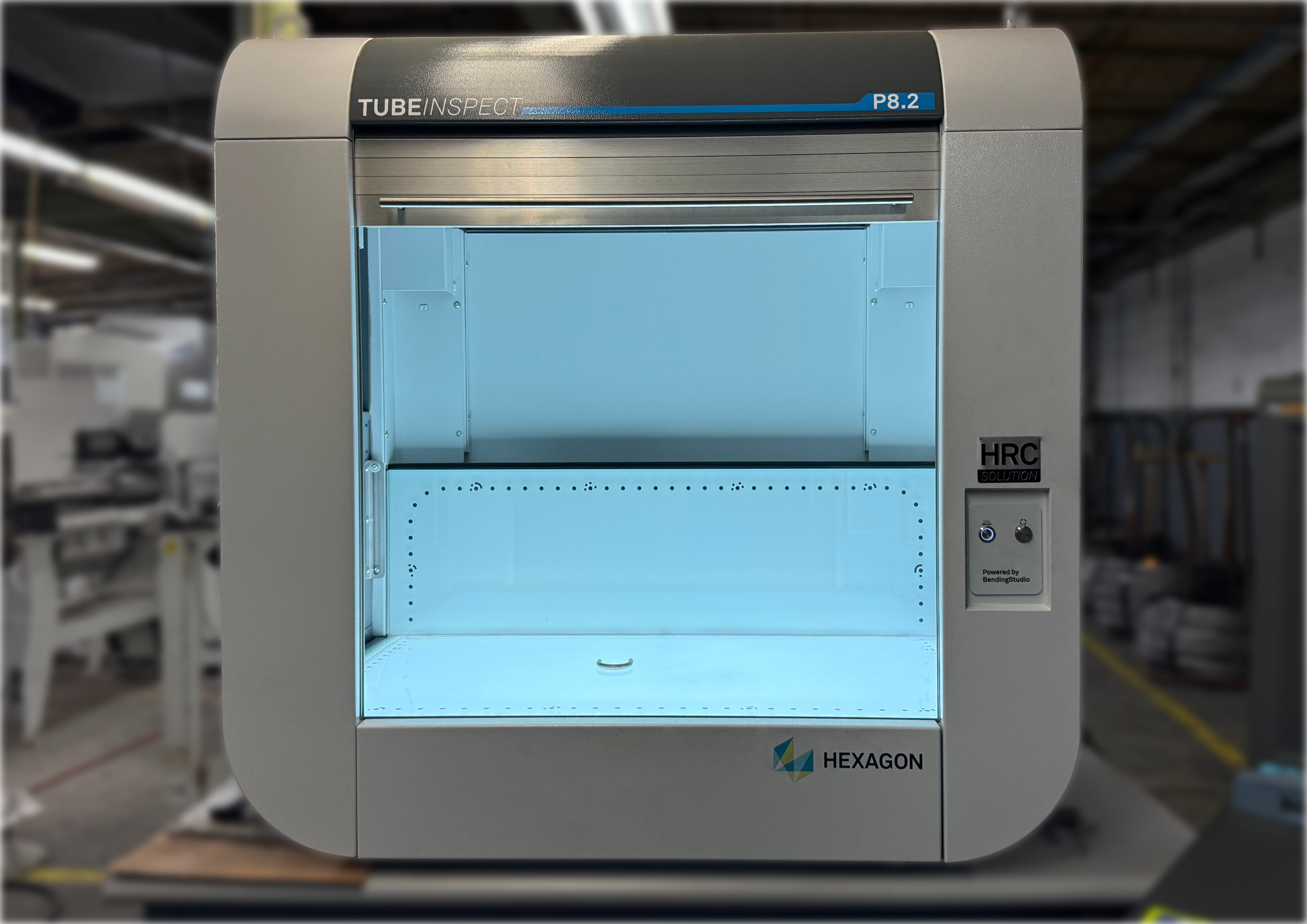

Request a design checkHook End Types

Hooks can be produced with a wide variety of end types, all of which varies in design based on your design’s needs. As one of the industry’s leading manufacturers of paint hooks, we recommend discussing your requirements with a Newcomb Spring sales engineer who can verify manufacturing capabilities and will work to optimize your hook design. Our offered design assistance can enhance your design, ensure its function and fit, as well as lower production costs. Reach out today!

The following are a few of the hook end types that we’ve manufactured:

V-Hooks

V-hooks allow for easy insertion and stability, making them ideal for hanging items like wires and rods that can sit snugly within the V.

Get a quote

Round Hooks

Round hooks are gentle on items that are hung on them, reducing the risk of damage. They are commonly used for hanging fabrics.

Get a quote

Straight Legs

Straight legs have a long, straight reach. They are often used in industrial settings where hooks need to fit into tight spaces or hang items without bending around curves.

Get a quote

Custom Ends

Custom ends are designed for specific needs or applications where traditional ends will not work. The shape can be tailored to fit unique requirements, whether for specific load distribution or aesthetic considerations.

Get a quote

Metal Hook Applications

- Agriculture

- Apparel

- Automotive

- Home Organization

- Industrial Manufacturing

- Kitchen Organization

- Meat Hanging

- Painting

- Retail

- Sports & Recreation

- Warehousing

- and more!

Product Gallery

Below are just a small selection of the battery springs and contacts we have produced, including:

- AA Battery Contacts &Springs

- AAA Battery Contacts & Springs

- Battery Terminal Connectors

- Battery Spring Contacts

- Coil Springs

- Cylindrical Battery Contacts & Springs

- Wave Springs

- Constant Force Springs

- Contact Plates

- Contact Tabs

- Flat Springs

- Metal Strips

- Spring Loaded Electrical Contacts