Custom Extension Springs

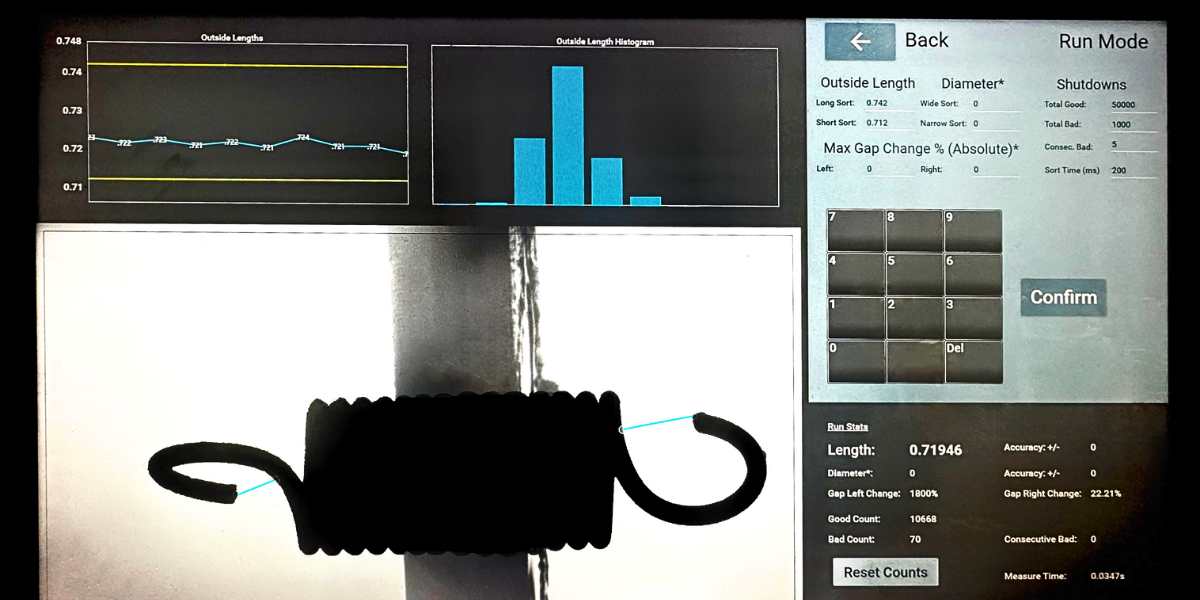

Newcomb Spring specializes in extension spring manufacturing, producing a diverse range of custom extension spring ends, sizes, and designs. Our commitment to quality and customer satisfaction ensures that every spring isn’t just made; it’s precision-engineered for optimized performance.

With more than a century of expertise in spring design and over half a billion extension springs manufactured each year, our team is ready to assist you with your product. We collaborate closely with you to enhance your design, helping to reduce production costs and ensure optimal fit, functionality, and service life for your precision extension spring.

Get an Extension Spring Quote Try our Spring CalculatorExtension Spring Capabilities

Material Shapes & Sizes

- .004 to .625 inches (.1016 to 15.875mm) in wire diameter

- Up to 2 inches (50mm) in bar stock

- Round wire

- Square wire

- Rectangular wire

- Special section wire

- and a large variety of materials available

Extension Spring Value Added Services

The following are only a portion of popular value added services we offer; this is not a comprehensive list. Please contact your local Newcomb Spring and discover what we can offer on your unique design.

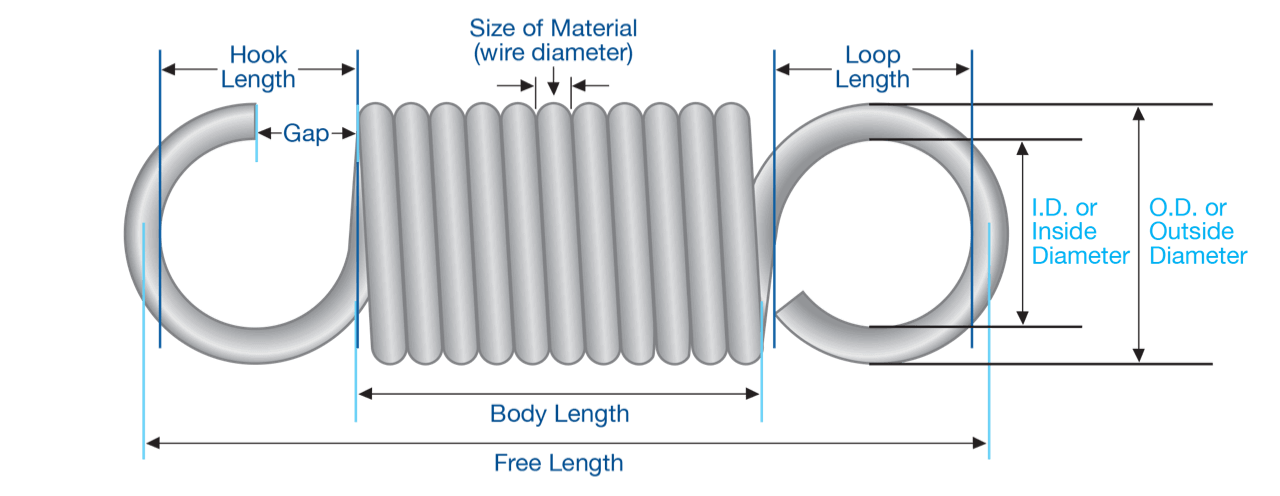

Extension Spring Design Information

What are Extension Springs?

Extension springs are tightly wound coils designed to store energy when stretched by applying force on their ends. They return to their original shape when the applied force is released, making them ideal for applications requiring controlled tension.

Design Assistance

The majority of extension spring failures happen in the hooks, please consult with Newcomb Spring’s design engineering team to configure your spring ends to maximize the life of your product. We provide design assistance to help bring your product to life - from heavy duty extension springs to micro extension springs. Our experts don’t just review your design for cost reduction; we offer insights that enhance the functionality and fit of your part. From concept to prototype to full production, our team is here to support you every step of the way.

We have worked with customers who have tried to get their part to function, and couldn’t get it working properly. We can step in and redesign the part in a way that will work. Our network of experienced engineers and design experts can work through these challenges with you and create custom designs that accomplish your goals.

Request a design checkExtension Spring Ends

The following are only a portion of the spring ends and shapes that our teams have designed:

Machine Hook

The most common end for extension springs; they are positioned over the center which allows for the direct transfer of force with efficient distribution.

Get a quote

Swivel Hooks

Increases movement and strength of the spring, while reducing the stress on it.

Get a quote

Extended Hook

Utilized in applications when the attachment point is far from the body of the spring or in a confined space.

Get a quote

Non-Hook Ends

Not all extension springs require a hook or loop. This is one example of a custom end that we produced to work in a unique application.

Get a quote

Threaded

Offers higher stability and enhanced strength while being able to absorb large forces.

Get a quote

Custom Shaped

We can create virtually any shaped end for your extension springs, including but not limited to: rectangle, teardrop, v-hook, expanded hook, etc.

Get a quote

Extension Spring Applications

- Aerospace

- Appliances

- Automotive

- Electronics

- Farm Machinery

- Furniture

- Medical Devices

- Sporting Goods

- Tools

- Toys

- Levers & Switches

- Fitness Equipment

- Industrial Machinery

- and more!

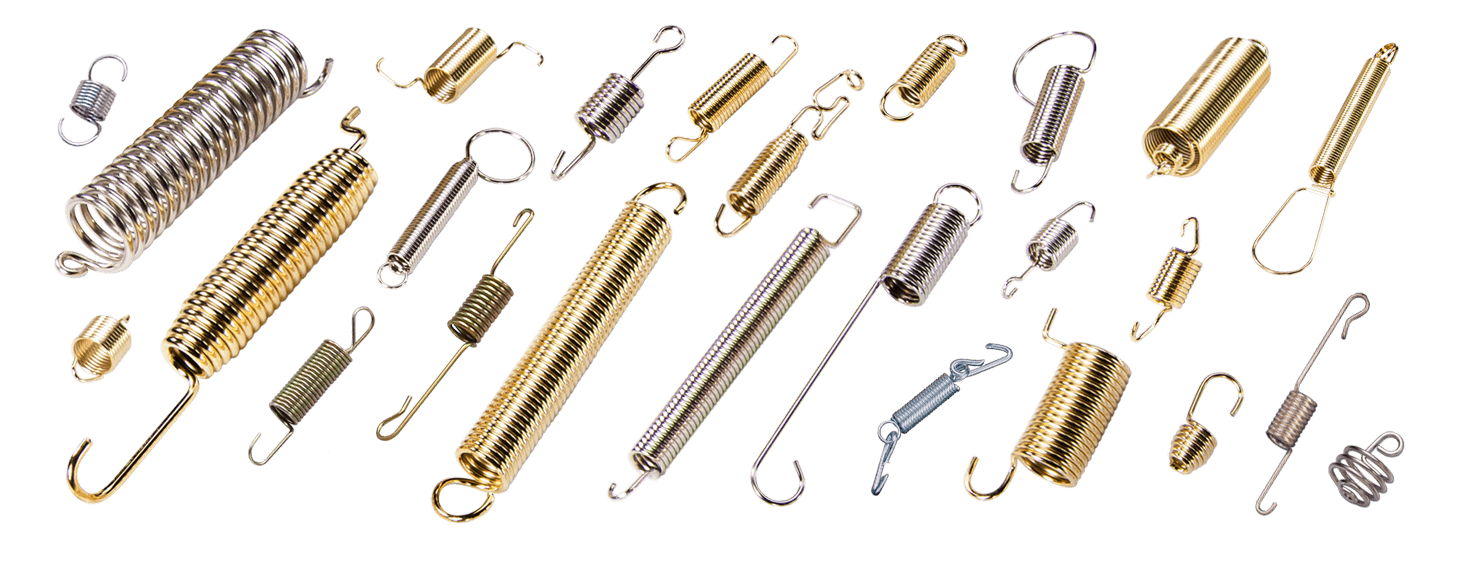

Product Gallery

Below are just a small selection of the extension spring shapes we have produced, including:

- Auger Spring

- Bungee Cord Ends

- Door Return Springs

- Drawbar Extension Springs

- Garter Springs

- Handle Springs

- Jumper Springs

- Medical Extension Springs

- Micro Extension Springs

- Recliner Chair Springs

- Stove/Oven Springs

- Threaded Inserts

- Emergency Brake Lever Spring

- Tie Down Springs

- Trampoline Springs