Standardizing Manufacturing

How ISO is Unifying Measurement Parameters and Symbols and why Newcomb is at the Forefront of the Change

- Originally published by Abbi Gillette

In the last decade, the spring industry notably lacked a true global standard that defines common characteristics and measurement methods. In 2013, the introduction of ISO 16249:2013 marked a significant milestone in standardization efforts. This standard began to define the symbols, characters, and methods of measurement for springs. The International Organization for Standardization (ISO) facilitates communication among international delegations, fostering discussions on standard improvement. “ISO brings global experts together to agree on the best way of doing things – for anything from making a product to managing a process. As one of the oldest non-governmental international organizations, ISO has enabled trade and cooperation between people and companies worldwide since 1946,” reads their website.

The Necessity of International Standards

Creating an international standard is crucial for several reasons. Perhaps the most prominent and expensive example dates back to 1998. The Mars Climate Orbiter was launched to study the climate of Mars. Unfortunately, the probe burned up in Mars’ atmosphere after missing its targeted altitude due to confusion between engineering teams. The American team used the imperial unit of pounds-force while the other team used the metric unit of newtons. This costly error could have been avoided if unified measurement standards had been established.

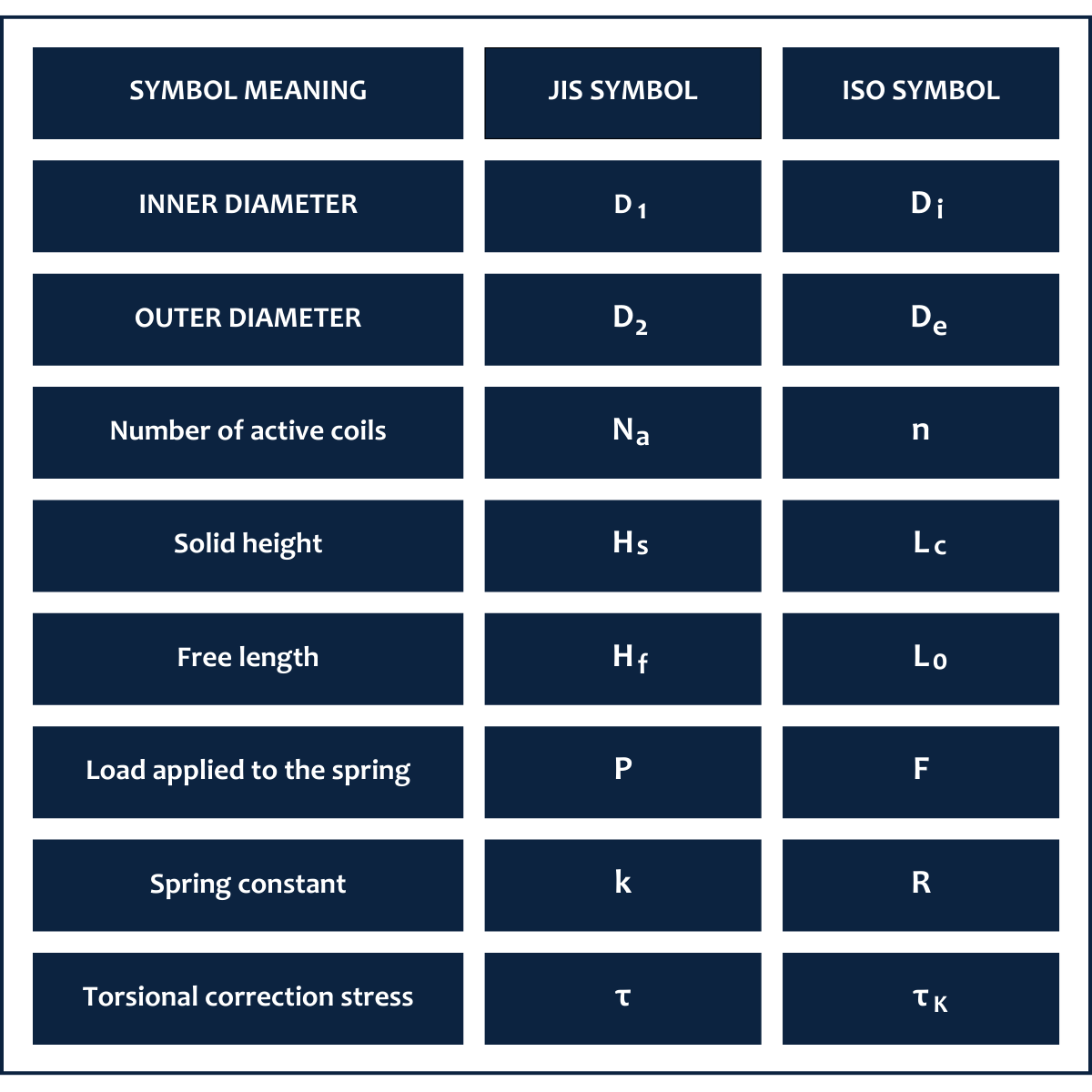

Similar issues happen in the world of spring design. One example is the discrepancies between the use of varying standards, like the Japanese Industrial Standards (JIS) and ISO. The symbols used in measurement can vary significantly, complicating design interpretations and leading to avoidable errors. Having a global standard and working with suppliers that adhere to this standard minimizes confusion and streamlines processes, increasing reliability across borders.

Ongoing Efforts Within Newcomb

ISO has continuously organized meetings with industry experts to pinpoint necessary changes for updating ISO 16249:2013. Keith Porter Jr., General Manager of Newcomb Spring of North Carolina, has been instrumental in discussions pertaining to extension springs. He has proposed significant updates to the ISO standard by providing insights and areas of improvement for load testing and the sequence of inspecting extension spring dimensions. “If we all follow the standard, regardless of what continent the spring is made on, the spring will be designed, tested, and documented in a universally understood way,” says Keith.

Daniel Lewis, Operations Manager at Newcomb Spring of Tennessee, sat in on the committee meetings as well. He emphasizes the importance of global standardization, “Standardizing spring characteristics and measurement methods keep expectations of all parties aligned. Newcomb Spring will benefit from refining these ISO standards for years to come by positioning ourselves as a preferred supplier in the eyes of a global customer base.”

International Collaboration

The 2024 ISO/TC 227 Spring Meeting in Italy welcomed representatives from 14 countries, including the United States, Italy, China, and Japan, to review and refine spring symbol standards. ISO/TC 227 is the technical committee for the spring industry, facilitating critical discussions and votes on standardization. This meeting focused on updating ISO 16249:2013, the standard for symbols.

Don Jacobson Ⅲ, Vice President of Business Development at Newcomb and current SMI President, attended the meeting as the Head of Delegation of the four-person United States panel. He brought votes, recommendations, and knowledge from a wide range of experts into the international spotlight. “As the world becomes more interconnected, it's essential for companies like Newcomb Spring to adapt and align with international standards. This ensures not only seamless collaboration across borders but also positions us to lead in innovation, quality, and efficiency. By participating in ISO standardization efforts, we're not just following trends—we're shaping the future of global manufacturing" he explains. The involvement of the United States delegation is crucial in minimizing future trade discrepancies by bringing US experiences, concerns, and expertise into the global discussion.

Newcomb is proud to be at the forefront of advocating for and adhering to ISO standards. All eight of our manufacturing locations are ISO 9001:2015 certified. We ship parts all over the world and recognize the crucial impact in efficiently communicating on a global scale. Our ongoing commitment to these standards not only positions Newcomb as a preferred global supplier but also demonstrates our dedication to industry advancement.

The next international ISO meeting for TC227 will be held in Hangzhou, China, in September 2025. Newcomb will continue to actively look for improvements in spring standardization to bring to future discussions.