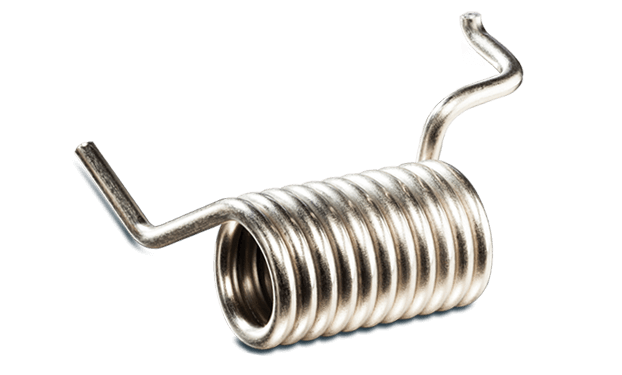

What Are Torsion Springs?

Torsion Spring Design Resources – Spring Overview

Springs used to apply a torque or store rotational energy are referred to as “torsion springs”. The 2 most common types are single and double-bodied springs. Torsion springs are found in clothespins mechanisms, ratchets and various types of machine components. They are also used couplings between concentric shafts, such as in a motor and pump assembly. Torsion springs are generally mounted around a shaft or arbor, and must be supported at 3 or more points. Various kinds of ends are available to facilitate mounting.

Torsion springs are stressed in bending. Rectangular wire is more efficient in bending than round wire, but due to the premium cost of rectangular wire, round wire is preferred. If possible, a torsion spring should always be loaded in a direction that causes its body diameter to decrease. The residual forming stresses are favorable in this direction, but unfavorable when the spring should always be loaded in a direction that causes its body diameter to decrease. The residual forming stresses are favorable in this direction, but unfavorable when the spring is loaded in a direction that increases body diameter. Unless there are unfavorable residual stresses in the end bends, spring makers normally heat-treat these springs at a low temperature to stabilize the end positions rather than to fully stress relieve them. If the direction of loading tends to increase body diameter, the spring maker should be advised to stress relieve the springs.

Content Copyright Spring Manufacturers Institute, Inc.

This information is attributed to, and provided courtesy of, the Spring Manufacturers Institute, Inc. (SMI). Newcomb Spring and SMI provide this as advisory information only, and disclaim any and all liability of any kind for the use, application or adaption of material published on this web site.