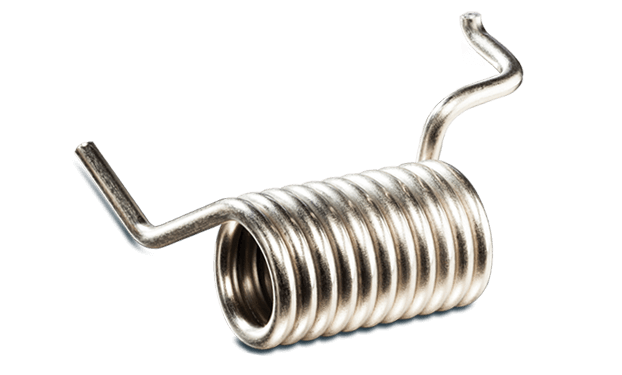

Double Torsion Springs

Torsion Spring Design Resources – Double Torsion Springs

Since it became First in Forming, Newcomb Spring has provided expert spring manufacturing capabilities. Our precision double torsion spring components are used in a wide variety of industries, and manufactured using standard, semi-precious and precious spring materials to meet customer and application requirements

Precision Manufacturing of Double Torsion Springs

All of our double torsion springs are custom manufactured to meet customer design and tolerance requirements. We manufacture torsion springs with:

- Wire Diameters from 007 to .625 Inches

- Bar Stock Up to 2.0 Inches

- Custom Double Torsion Spring End Options to Meet Your Needs

- Round, Rectangular, Square & Special-Section Wire

Design of Double Torsion Springs

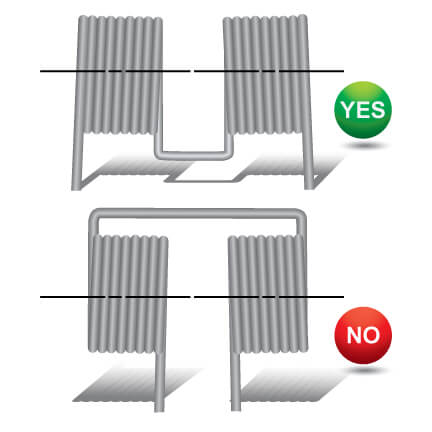

Double-bodied torsion springs are designed using the same methods as for single-bodied torsion springs. The rate for a double-bodied torsion spring is equal to the sum of the rates for each component. For the same wire diameter, coil diameter and wire length, double-bodied torsion springs have rates two times those of single-bodied types. Double-bodied torsion springs should be designed so they are coiled out from the center rather than in from the ends.

Preferred Winding For Double-Bodied Torsion Springs

While Newcomb Spring can produce double torsion springs in both the preferred wind and the non-preferred wind body shapes, the preferred configuration lowers production costs.

Sections of this Content Copyright Spring Manufacturers Institute, Inc.

Portions of the information on this page is attributed to, and provided courtesy of, the Spring Manufacturers Institute, Inc. (SMI). Newcomb Spring and SMI provide this as advisory information only, and disclaim any and all liability of any kind for the use, application or adaption of material published on this web site.