Cutting-Edge Precision: Waterjet Machines and Aluminum Plates

- Originally published by Abbi Gillette

What is a waterjet machine?

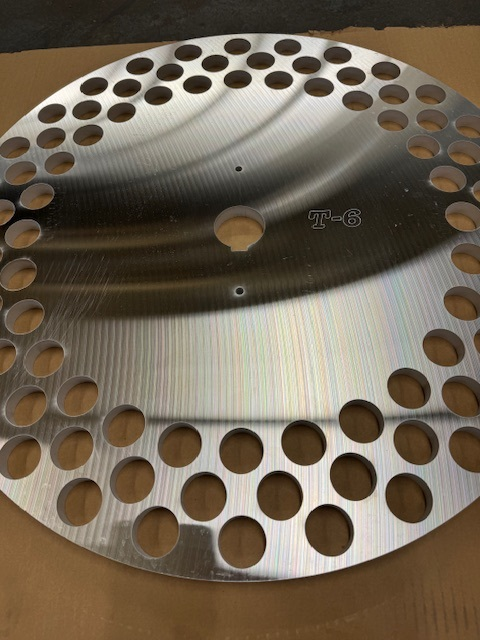

A waterjet machine is a robust, industrial grade cutting tool used on a wide array of both soft and hard materials. However, unlike traditional sharp blades, a high-pressure stream of water is released through a narrow nozzle to make the precise cuts. The intensely focused pressure gradually chips away at the material until the desired cut is achieved. This form of precision cutting and etching is particularly valuable for working with a variety of metals and thicker materials that would be difficult to pierce otherwise. At Newcomb Spring, we utilize waterjet machines to craft aluminum spring end grinding plates used in our plants across the country.

Waterjet machines can be highly customized to adapt to the specific material that is being used. Not only are there numerous nozzle options that are available for specific cuts, but factors such as water pressure can be meticulously adjusted to accommodate virtually any material. The machine operates using computer-based programs that instructs it precisely how to cut the material – like how a Cricut machine works, but on a larger scale and using water as the medium.

Traditional grinding plates vs aluminum

Traditionally, our grinding plates have been crafted from plywood and cut in-house as needed. Although they perform well for small production runs, they tend to wear out rather quickly with prolonged use. A plywood plate typically grinds around 5000 pieces before needing replacement, although this lifespan can vary heavily dependent on several factors. Another drawback is that the keyway (the middle opening that slides onto the key rod) gradually widens over time due to wear and the jarring it experiences, especially at startup. As a result, the grind on spring ends become uneven and take longer to achieve a square finish.

In contrast, the aluminum plates manufactured by Newcomb Spring of Connecticut are exceptional. Not only are they significantly more durable than plywood, but they boast an impressive extended lifespan. This plays a huge part in running large production orders that would otherwise eat through a multitude of wooden plates. With aluminum plates, the grinder can continuously operate without interruption, significantly reducing the time needed to grind parts and contributing to quicker delivery to customers.

Another advantage of the aluminum plates is the resilience of the keyway. The strong aluminum plates withstand the impact of resistance force during grinding without deformation or stretching. This keeps the plate securely attached to the key rod without any play. As a result, this assists in keeping everything steady and level as parts are ground from start to finish. Not only does this make the machine run smoother with fewer jams, but we achieve more precise grinding.

Additionally, some of our divisions, along with many other spring manufacturing companies, utilize carbon steel plates as an alternative to plywood. While these carbon steel plates offer comparable durability and lifespan to aluminum plates, they are significantly heavier. The increased weight leads to challenges in safely mounting and dismounting the plates, as lifting them can pose a hazard. There is also an increased risk of team members cutting their hands while handling the heavy steel plates. On the other hand, aluminum plates are much lighter, decreasing the lifting hazards and cutting risks associated with carbon steel plates, thereby enhancing workplace safety.

Overall, the durability, resilience, and lifespan of the aluminum plates make them a far superior option to plywood for large production runs. Although comparable to carbon steel, aluminum is much lighter and safer to work with, making them the preferred choice here as well. Thanks to our available waterjet machine, we have the freedom to choose what material is the best option on a per production run basis.

Why Newcomb?

At Newcomb Spring, we take immense pride in our processes, including the quality of the machines and equipment we employ. To maintain the high standards we’ve set within the industry, we make strategic investments and uphold a strong sense of pride in our equipment.

Our recent acquisition of a waterjet machine for manufacturing our own aluminum grinding wheels has significantly enhanced our control over custom orders. This technology allows us to precisely create the components needed to meet your specific requirements. As pioneers in forming, we remain at the forefront of technological advancements – a commitment we hold dear at Newcomb.

When it comes to spring needs, choose Newcomb Spring. You will encounter the exceptional quality that defines our company’s reputation.

As advancements in technology continue to develop, we want to be at the forefront of innovation. We take pride in our in-house machines and capabilities to bring you high-quality components to match! Our Kando Tech Centers are dedicated to engineering a perfect spring design for your custom needs. Request a Quote today or contact sales@newcombspring.com for more information.